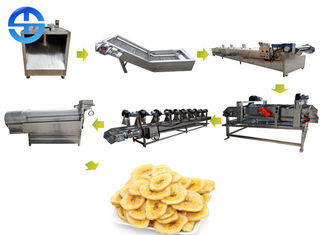

Commercial Full Automatic Banana Plantain Chips Production Line

Introduction:

Fried banana plantain chips is more and more popolar in snacks industrial because of it's healthy and nutrious. It is made of banana: peel, cut, fry, flavor, pack.

We are the professional manufacturer of the full automatic potato chips machine, basiced on customers demands, we designed top quality whole line solution for satifying different capacity demands: 10-1000kg/h.

banana chips production line process:

peeling machine-cutting machine-frying machine-flavoring machine-packing machine.

Specification:

Our full –automatic thai babana chips making machine adopts the most advanced banana chips making mahcines. Banana chips are crisp snack food similar to potato chips. Banana chips are mornally made from under-ripe fruits by frying the slices in oil. The pricessing capacity we supply is from 50kg/h - 400kg/h.

|

|

|

|

|

|

|

|

0.75kw/380v/50Hz

|

540*820*1060mm

|

|

|

|

|

1700*1000*800mm

|

|

|

|

|

3000*1030*1350mm

|

|

|

Banana chips blenching machine

|

|

4500*1130*1400mm

|

|

|

Cold air dewatering machine

|

|

4000*950*1880mm

|

|

|

Electric chips frying line

|

|

6200*2000*2000mm

|

|

|

Banana chips de-oiling machine

|

18.75kw/380v/50Hz

|

4000*1000*2250mm

|

|

|

Banana chips flavoring machine

|

11.75kw/380v/50Hz

|

2800*900*2300mm

|

|

|

|

|

3700*800*1130mm

|

|

|

|

6 kw/380v/50Hz

|

|

Features:

1. Plantain Chips Making Machine is designed for processing potatoes into delicious potato chips,potato crips or frech fries and packing ot potato chips with excellent quality and less fat pickup.

2. Final products: fried chips flat (and wave shape), frech fries, Or other products. also cam be adjusted to produce frozen frech fries, with packing machine to pack into bags.

3. Plantain Chips Making Machine has the advantages of low investment, low energy consumption, many functions, small volume, high profit, convenient maintenance and so on.

4. The whole Plantain Chips Making Machine is composed of hoisting,cleaning and stripping, selecting,slicing (strip), blanching, dehydration, frying, deoiling, flavoring, packing and auxiliary equipment.

5. Raw materials can be fresh potatoes, also can be used for other root vegetables, such as sweet potatoes,purple sweet potato, taro, cassava, etc.

Different Between Plantain Chips and Banana Chips

1. Banana skin is Thinner than plantain.

2. Banana can eat directly,pantain need cooking.

3. Banana have more sugar than plantain.

4. Banana and plantain can both make banana chips.

Single machine introduction:

1. Hoist: Raise the material automatically, convenient and quick, save manpower;

2. Potato washing and peeling machine: integrates the function of washing and peeling, and it can be used for processing potatoes, carrots, radish, sweet potatos and other root vegetables;

3. Selection machine: Remove the rotten parts of potatoes,Improve quality;

4. Potato cutting machine: used for cutting the potatoes into slices, strips or cubes and also suitable for other root vegetables, like carrots, cassava etc.;

5. Air Bubble washing machine: Cleaning and protecting color;

6. Potato slice blanching machine: used for blanching the slices, strips or cubes of potatoes or any root vegetables. The main purpose of blanching is to remove potato starch and ensure the slices brightness and crispy;

7. Air-dryer: Remove the surface water of the potato chips by cooling air,transported to the fryer;

8. Electrically heated frying line: Fry potato chips,improve color and taste;

9. Air drying machine: Shake off the excess oil of the potato chips surface;

10. Hoist: Transport the fried potato strips to the seasoning machine;

11. Seasoning machine: Evenly seasoning after the ingredients according to needs ;

12. Potato chips packing machine: improves the packing efficiency and saves a lot of time. As fried potato chips are fragile, the nitrogen is necessary to keep food fresh, tasty and without damage.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!