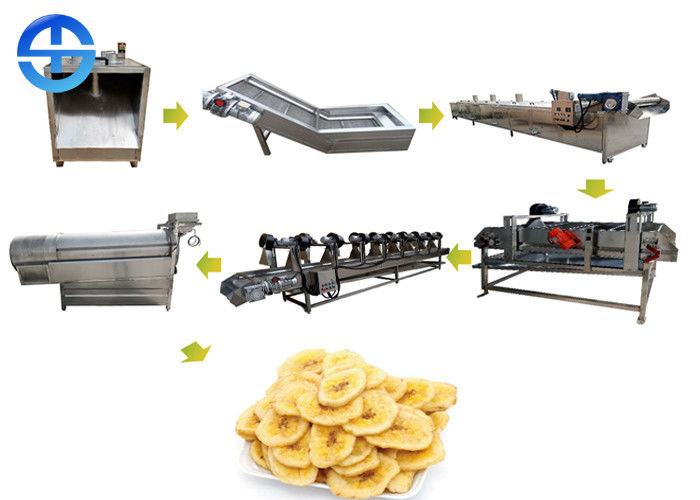

Stainless Steel Full Automatic Banana Chips Making Machines Plantain Chips Production Line

Introduction:

The line include plantain/Banana slicing machine,blanching machine,dewatering machine,frying machine,deoiling machine,flavoring machine and packing machine.All machines are of stainless steel,high quality,low energy consumption,low investment,big profit,easy operation and maintenance.

Different Between Plantain Chips and Banana Chips

1. Banana skin is Thinner than plantain.

2. Banana can eat directly,pantain need cooking.

3. Banana have more sugar than plantain.

4. Banana and plantain can both make banana chips.

Single machine introduction:

1. Hoist: Raise the material automatically, convenient and quick, save manpower;

2. Potato washing and peeling machine: integrates the function of washing and peeling, and it can be used for processing potatoes, carrots, radish, sweet potatos and other root vegetables;

3. Selection machine: Remove the rotten parts of potatoes,Improve quality;

4. Potato cutting machine: used for cutting the potatoes into slices, strips or cubes and also suitable for other root vegetables, like carrots, cassava etc.;

5. Air Bubble washing machine: Cleaning and protecting color;

6. Potato slice blanching machine: used for blanching the slices, strips or cubes of potatoes or any root vegetables. The main purpose of blanching is to remove potato starch and ensure the slices brightness and crispy;

7. Air-dryer: Remove the surface water of the potato chips by cooling air,transported to the fryer;

8. Electrically heated frying line: Fry potato chips,improve color and taste;

9. Air drying machine: Shake off the excess oil of the potato chips surface;

10. Hoist: Transport the fried potato strips to the seasoning machine;

11. Seasoning machine: Evenly seasoning after the ingredients according to needs ;

12. Potato chips packing machine: improves the packing efficiency and saves a lot of time. As fried potato chips are fragile, the nitrogen is necessary to keep food fresh, tasty and without damage.

Features:

1. Small scale banana chips making machine is hot sale,we also have 100kg/h, 150kg/h, 260kg/h, 400kg/h plantain chips production line for your choose.

2. The philippine banana chips making machine is high quality,all materials is stainless steel.

3. The banana chips frying machine have electric and gas heating type for your choose.

4. The banana chips production line price depend on machine capacity.Before ask our price,you can tell us your output firstly.

Technical Parameter

| No. |

Machine Name |

Specifications |

| 1 |

Banana Chips Cutting Machine |

Dimension:650*550*900mm

Capacity:400-600kg/h

Power:0.75kw

Weight:100kg

|

| 2 |

Lifting Machine |

Power:0.75kw |

| 3 |

Blanching Machine |

Dimension:1300*1400*1800mm

Capacity:100-150kg/h

Weight:300kg

Power:36KW

|

| 4 |

De-Watering Machine(above discharge) |

Dimension:1250*1250*1550mm

Power:1.5kw

|

| 5 |

Lifting Machine |

|

| 6 |

Electric Frying Machine |

Dimension:1300*1400*1800mm

Capacity:100-150kg/h

Weight:300kg

Power:36kw

|

| 7 |

De-Oiling Machine (under discharge) |

Dimension:1250*1250*1550mm

Power:1.5kw

|

| 8 |

Lifting Machine |

Dimension:2000*650*1300mm

Power:0.75kw

|

| 9 |

Seasoning Machine |

Dimension:1500*700*1600mm

Power:1.5kw

|

| 10 |

Automatic Packing Machine |

Packing Speed :30-60Bags/min

Total Power :2.5KW/220V

Measure Range :200-1000ML

Dimension:820x980x1980(mm)

Bag Size Making :L: 80-280mm W: 80-220mm

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!